Flux-ing Around

So what is Flux, and what part does it play in our model building?

If you ask the internet, it will give you a bunch of words that will say something like “Soldering flux is a chemical agent used to clean and prepare metal surfaces for soldering. It helps remove oxidation and impurities, allowing solder to flow smoothly and create strong, reliable connections. Flux ensures that the solder adheres properly to the metals, improving the overall quality of the solder joint.”

But basically, it’s a cleaner.

It comes in many forms. The most common type is mostly for electronics which comes as a coil and the flux is built into it. The other two in order of easy to find is, a paste which we have only used on brass not white metal and in liquid form. The most common liquid form found here in NZ for years was Duzall flux, in its distinctive green bottle, often referred to as “Does all”, is a general-purpose liquid soldering flux made from zinc chloride. Although it does seem to becoming harder to find these days.

Duzall is not our weapon of choice for soldering white metal castings with low melt solder. That said it can be used. However, most of the people we know that do use it, also water it down.

DCC concepts have a good readymade flux. DCC Concepts Fluxes. We have used this one back when Acorn models in Christchurch used to stock it, but they haven’t had it in stock for some time. We guess getting it into the county might be a bit of a problem.

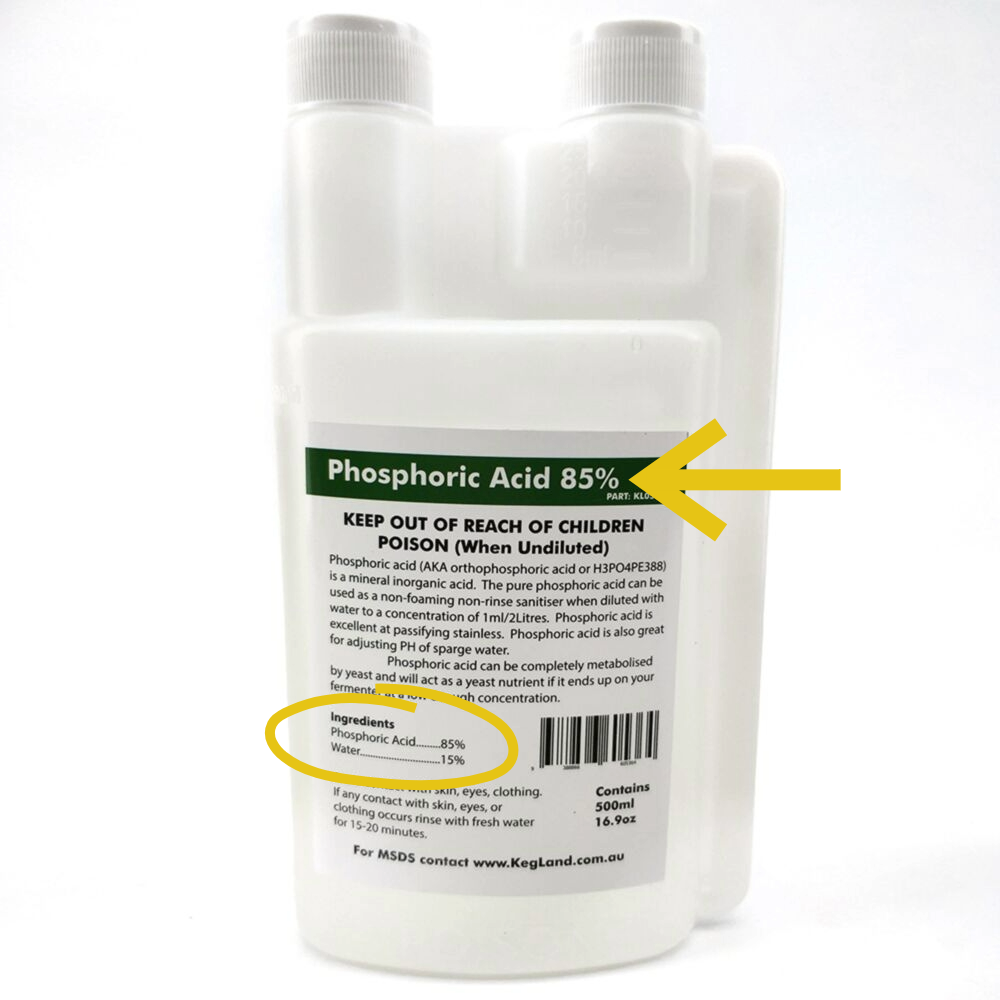

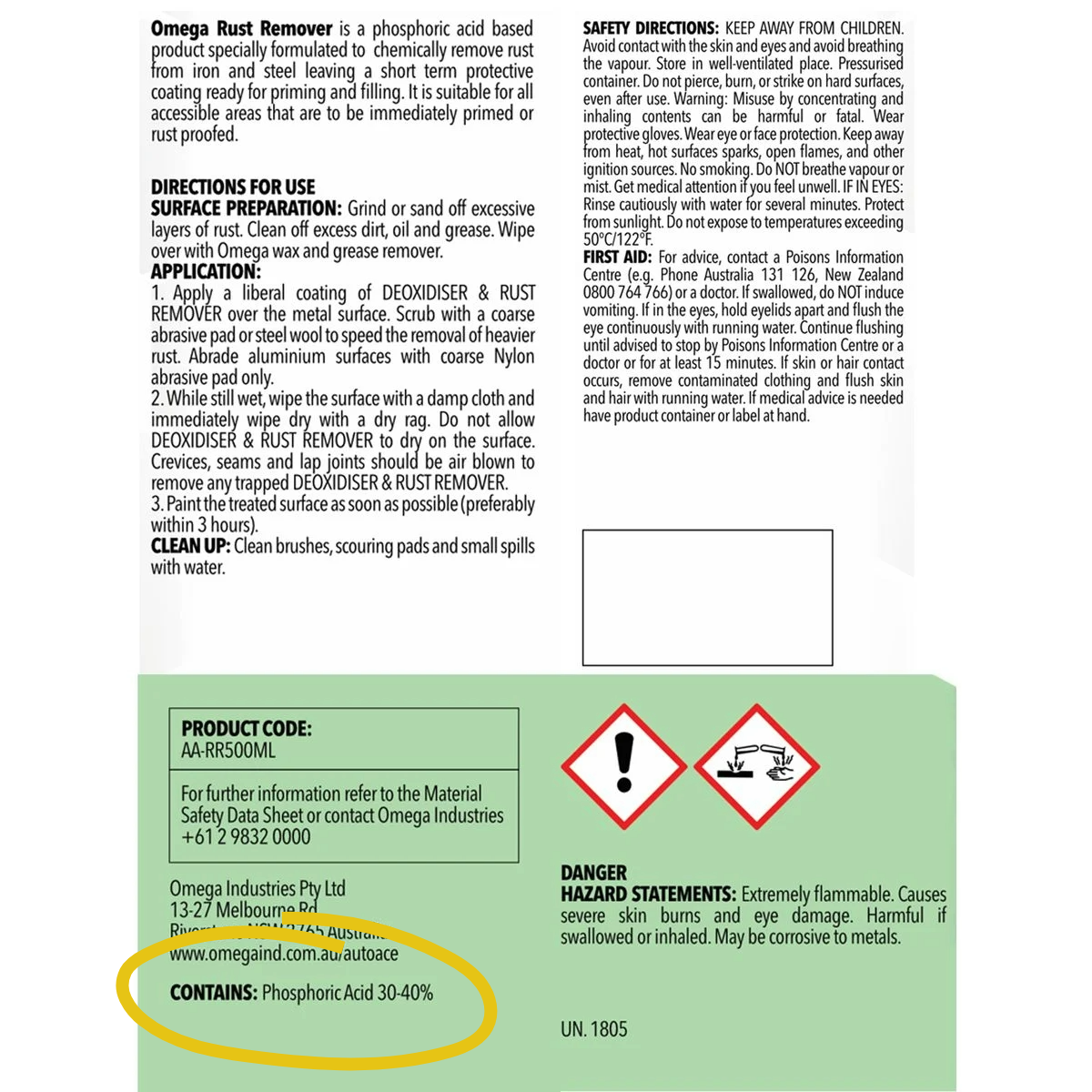

Our weapon of choice is Phosphoric Acid. When we started using it was it was difficult to come across. However, now it is much easier to find as people that do home brewing use it for cleaning the brewing kegs. Chances are that your local home brew shop will have it or can get it. The second place to find it is in Rust converters / removers like Omega Deoxidiser & Rust Remover

So you have the acid, now what?

Acquire a 30ml glass bottle. Thay come in meany formats: eye dropper in the lid, a plane lid and brush in the lid to name a few. But you will want some way to measure it out, an eyedropper for measuring is ideal. These are all common on the internet, are pretty cheap and your local chemist probably also has them. Also, the size of the bottle isn’t too important either if you go through it a lot, go bigger. It will just change the ratios that you put in it. But 30ml is the size that has worked best for us

Michael’s preferred flux delivery system is the bottle with the eye dropper in the lid, which is fine. But sometimes a drop is too much and eventually the rubber that makes that dropper work, will suffer the consequences of living with an acid and need replacing. My preferred flux delivery method is to use a cotton bud. So, I get the bottles with the plain lid. Coincidentally, it fits in the container that the cotton buds come in! Which is excellent for containing a liquid when you want to travel to a train show to build trains.

Next. Check out what your percentage of acid is. For us our bottle is 100%, most of the brew shops will have it at anywhere between 80 & 90 % and the rust converters a bit lower. This just means for us we will put about 5 drops in our 30ml bottle and top up with water. If you are around the 80% acid mark you might want to go for 9 -11 drops and top up with water for the rust converters 3 full droppers worth. From all the ones we have seen if it is less then 100% chances are its mixed with water

It doesn’t have to be exact; it just has to do its job. If the solder isn’t flowing or nothing is sticking add another drop or two in the top and make that your base for future. If you are coughing on fumes, dial back the number of drops next time or (lol) its that, or you have your head to close to the project! (that’s normally my issue 😊 every now and then you need a reminder your too close)

Happy soldering. With a note:

For longevity it is good practice (no mater what flux you decide to use) to give the project a wash. Some people give them a wash in detergent at the end of the projects build. In this house we rinse it under the tap and give it a scrub with a plastic stiff bristle brush (like a toothbrush dedicated to the job) after each soldering session. Either way is better than doing nothing.

For more information on soldering in general see Soldering - The "Black Art" De-mystified from DCC concepts.